How do we make the things where we make the things?

Richard O Hegarty, Sean Hogan, Rebecca O Connor, Vishaka Reddy, Katie Barry, Rosemarie MacSweeney, Matthew Reddy

Try typing any combination of the words “innovation” and “manufacturing plant” into a search engine. 99% of results returned will be related to manufacturing plants that use innovative techniques to manufacture anything ranging from beer to prefabricated homes.

But what about the manufacturing-buildings themselves? What methods, materials and modern approaches are used to construct these, and what innovations will pave the way for future factories?

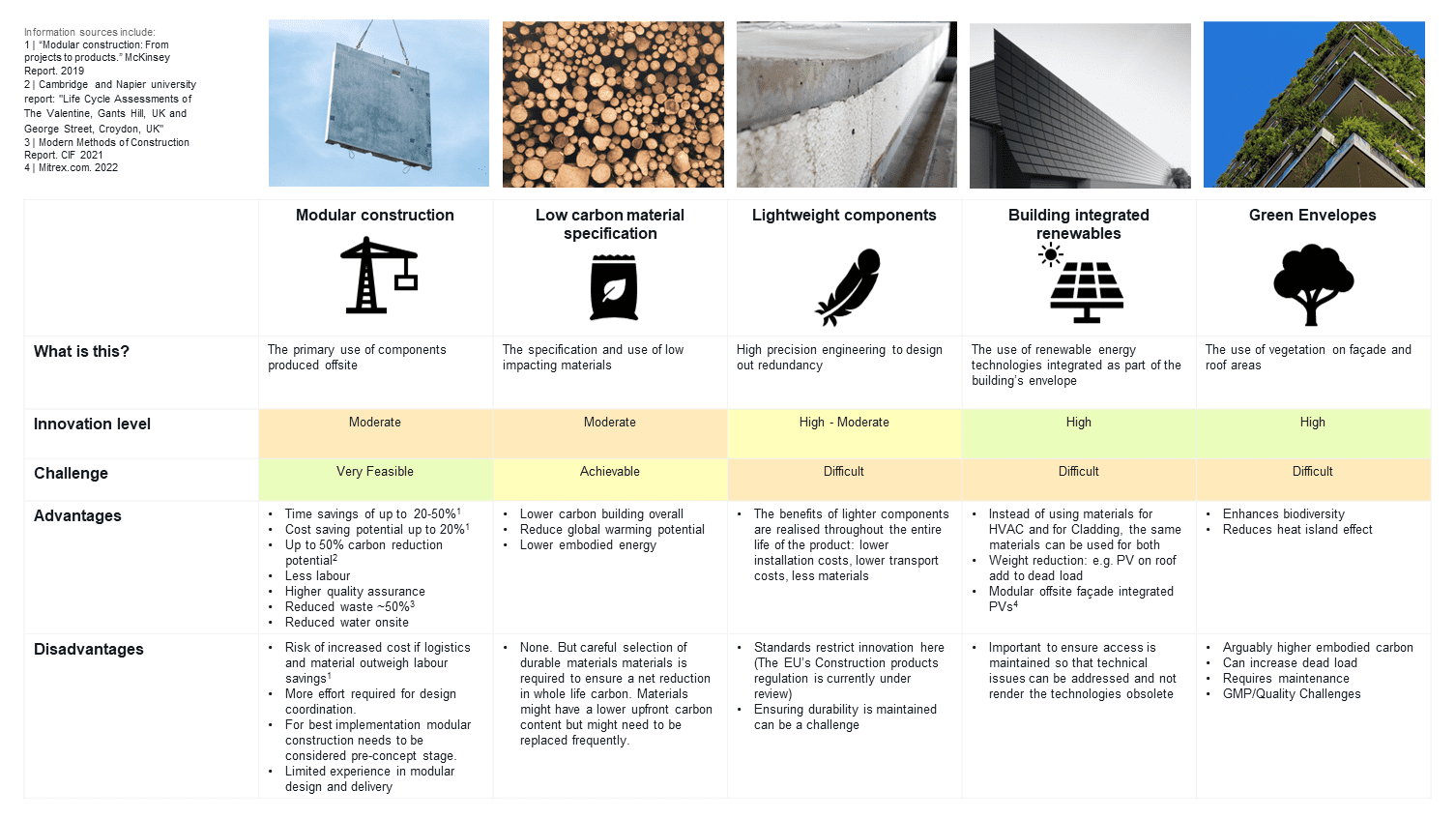

RKD’s Sustainability + Research team has developed a matrix of 5 innovative solutions that could be used to construct the fabrication facilities of the future – ranging from simple design changes by way of material specification, to building integrated renewable technology solutions. The list is non-exhaustive, and focuses on the building itself rather than the operation of the facilities themselves, for which hundreds of innovative solutions exist.

Moving from left to right of the matrix below, the proposed items increase in both the level of innovation required, but also the technical and practical challenges in implementing them.

1. Modular construction | Design to deconstruct

Modular construction is not a new construction typology, but despite the reported savings in time, cost and carbon [1], [2], the rate at which it is being adopted globally differs considerably from one country to the next. Although a broader category than just modular construction, the share of offsite construction used in the residential sector, for example, was 45% in Scandinavian countries in 2019, while in the UK, the figure dropped to just 5%, and to 3% in the US.

Manufacturing buildings present a unique case study for the application of modular methods. The lifetime of products being produced in these facilities, as well as the methods and equipment used to manufacture them, are considerably lower than the lifespan of the building itself. What this means is that the function of the building is likely to change several times during the potential lifetime of the structure, and, as the function changes so does the fabric’s needs.

Designing these buildings to be adaptable would extend the lifetime of the structure and its components, reducing the demand for virgin materials to build new structures, the need for energy to move and construct, as well as all the associated greenhouse gas emissions. Designing for deconstruction and demountability, using modern prefabrication methods, enables the realisation of these efficiencies.

2. Low carbon material specification | Specify ‘sustainable’ but think ‘function’

Specifying low carbon materials is easy. Specifying low carbon materials and products that provide the same function, for the same period of time and deliver client needs, is where the challenge lies. This is where RKD differ to others.

We use design thinking to broaden the thought process, question the assumed functional requirements and expected lifespans and present practical and implementable sustainable solutions.

For example, one specific façade solution might embody 50% less carbon than another solution initially, but it may require replacing 3 times within the lifespan of that alternative façade, thus resulting in a 50% higher embodied carbon when considered from a whole life carbon perspective. This is an example where the specification of durable, resilient materials is advantageous – an advantage which is likely to become more important in a world with ever-more-frequent extreme weather events. A world where our building materials will be tested more than ever.

Specifying low carbon solutions which deliver project objectives and client needs is therefore not a trivial lowest-initial-carbon-is-best exercise. It requires holistic thinking of the interrelationship between sustainability, longevity and functionality.

Manufacturing facilities, once again, provide a unique case study for designers. Optimising the fabrication of the plethora of products and product-families necessitates different interior conditions. The successful design of a factories’ envelope – the boundary between indoor and outdoor, between control and chaos – is paramount to the efficient delivery of the building’s function.

3. Lightweight components | Use less – achieve more

Sustainable construction starts with efficiency. Although off-the-shelf solutions require little thought processing and hence time and energy, they rarely provide the most sustainable, or indeed most efficient, solution.

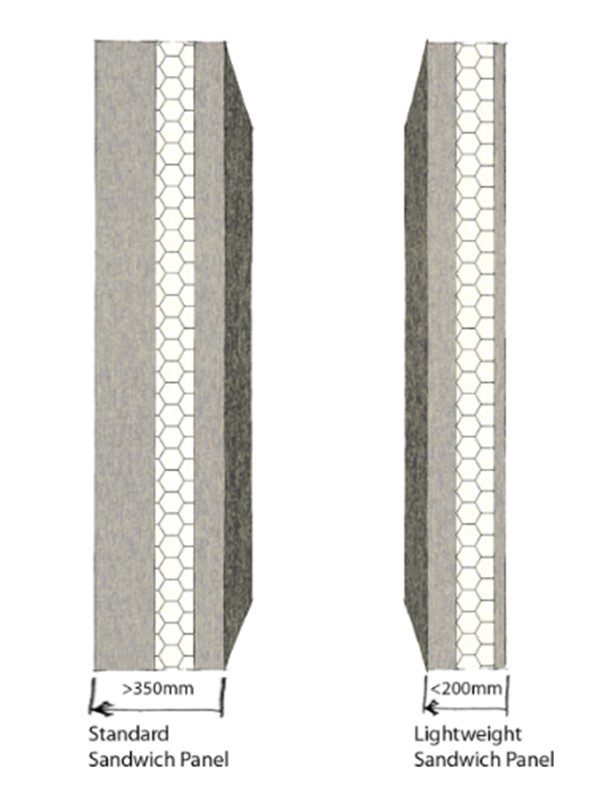

In one Irish-led lean construction innovation project, a consortium of industry and academic bodies across Europe, developed a prefabricated concrete cladding solution for building renovation which was 50% lighter than the standard precast concrete equivalent but which met all structural, thermal and durability requirements [3].

Although more expensive, and hence edging towards the difficult-to-achieve-in-practice side of our matrix, it presents a case study of where innovative design and research can be used to deliver the same function while using less material.

Image credit: Oliver Kinnane – [3]

4. Building integrated renewables | Fabric activation

The role of the building’s skin in contemporary design is to provide passive functions – to separate heated/cooled space from the outdoor climate, to minimise or maximise daylighting, to enable private spaces, etc.

That’s not, however, how nature works.

The human façade, in the form of skin, actively manufactures vitamin D from sunlight which is used internally to maintain bone, teeth and muscle health, while other animals, such as alligators, vary their heart beats to regulate their body temperatures through a fractalized system of veins in their skin in response to ques from local and external temperatures [4], [5].

Biomimetic design enables the realisation of the building’s skin as more than a passive feature. Building Integrated Photovoltaic (BIPV) technologies are one nature-mimicking solution which aim to activate the fabric of a building using photovoltaic solar cells to absorb solar energy and convert it into electricity for the building’s needs.

Manufacturing facilities typically use most energy during the day when solar radiation is highest and are located outside urban areas, where aesthetic requirements are less stringent, therefore presenting a strong case for the application of BIPVs.

Image credit: Visual components – Unsplash

5. Green envelopes | Fabric function 2.0

On the far right side (highly innovative / highly challenging end) of our matrix of solutions we have located green envelopes. A solution which boasts an ability to enhance local biodiversity while reducing heat island effects. Benefits which primarily serve urban environments where the demand for space is more intense and thermal mass is high, but which might be less suitable to manufacturing facilities.

Creative design thinking can be used to enable green facades serve a function in certain circumstances however. For example, the Jakob factory in Ho chi Minh city in Vietnam included a stacked green façade as part of their passive cooling system in one of their rope system manufacturing facilities.

Final thoughts

The manufacturing industry is constantly developing new products and processes. At the same time, the outdoor environment is becoming more unpredictable year-on-year as a result of climate change. And in between these two rapidly changing systems, we have the manufacturing building itself. A building which consequently needs to be more sustainable, more resilient [6] and more prepared for change than ever before.

Achieving these seemingly conflicting demands challenges designers to be creative and to embrace innovations in the construction industry. A challenge we are excited to take on.

References

[1] N. Bertram, S. Fuchs, J. Mischke, R. Palter, G. Strube, and J. Woetzel, “Modular construction: From projects to products. McKinsey Report.,” Cap. Proj., p. 34, 2019.

[2] A. Morby, “News article on the Report: ‘Life Cycle Assessments of The Valentine, Gants Hill, UK and George Street, Croydon, UK,’” Construction Enquirer, 2022. https://www.constructionenquirer.com/2022/06/06/factory-made-homes-cut-carbon-emissions-by-45/ (accessed Dec. 12, 2022).

[3] R. O’Hegarty, O. Kinnane, M. Grimes, J. Newell, M. Clifford, and R. West, “Development of thin precast concrete sandwich panels: Challenges and outcomes,” Constr. Build. Mater., vol. 267, p. 120981, Jan. 2021, doi: 10.1016/j.conbuildmat.2020.120981.

[4] S. C. Fu et al., “Bio-inspired cooling technologies and the applications in buildings,” Energy Build., vol. 225, p. 110313, Oct. 2020, doi: 10.1016/j.enbuild.2020.110313.

[5] C. Martín-Gómez, A. Zuazua-Ros, J. Bermejo-Busto, E. Baquero, R. Miranda, and C. Sanz, “Potential strategies offered by animals to implement in buildings׳ energy performance: Theory and practice,” Front. Archit. Res., vol. 8, no. 1, pp. 17–31, Mar. 2019, doi: 10.1016/j.foar.2018.12.002.

[6] European Commission, Level(s). Accessed: Jan. 09, 2023. [Online]. Available: https://ec.europa.eu/environment/eussd/pdf/Level_publication_EN.pdf